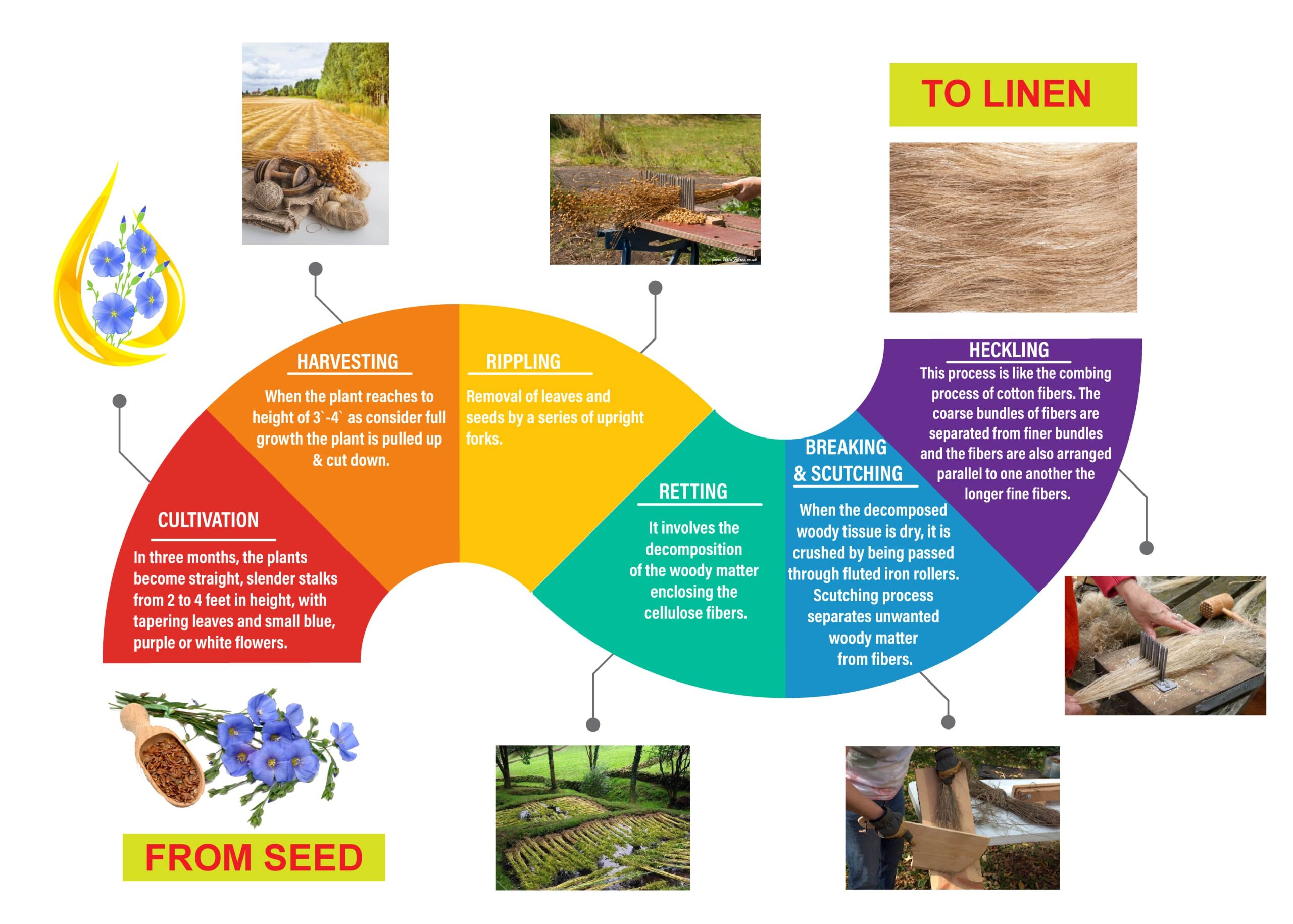

Production Flowchart of Linen or Flax Fibre

Last updated on June 22nd, 2023 at 05:12 am

Basically the flax fibre composed of cellulose. Linen yarn is made from fibres removed from the stem of the slender flax plant. These fibres, held together under the stem’s bark principally by a gummy substance, form the body of the flax plant. The fibre obtained from the stem of the flax plant was probably the first textile fibre to be used.

Linen Fibre Production Flow Chart

Cultivation

↓

Harvesting

↓

Rippling

↓

Retting

↓

Breaking and Scutching

↓

Heckling

| Stages | Description |

| Cultivation | In three months, the plants become straight, slender stalks from 2 to 4 feet in height, with tapering leaves and small blue, purple or white flowers. The plant with the blue flowers yields the finer fibre the others produce a coarser but strong fibre. |

Harvesting | When the plant reaches to height of 3`-4` as consider full growth the plant is pulled up & cut down. |

Rippling | Removal of leaves and seeds by a series of upright forks. |

Retting | It involves the decomposition of the woody matter enclosing the cellulose fibers. |

Breaking and Scutching | When the decomposed woody tissue is dry, it is crushed by being passed through fluted iron rollers. Scutching process separates unwanted woody matter from fibers. |

Heckling | This process is like the combing process of cotton fibers. The coarse bundles of fibers are separated from finer bundles and the fibers are also arranged parallel to one another the longer fine fibers. |

Thanks.