Importance of Roller Weighting | Advantages of Spring Weighting

Last updated on October 18th, 2023 at 12:13 pm

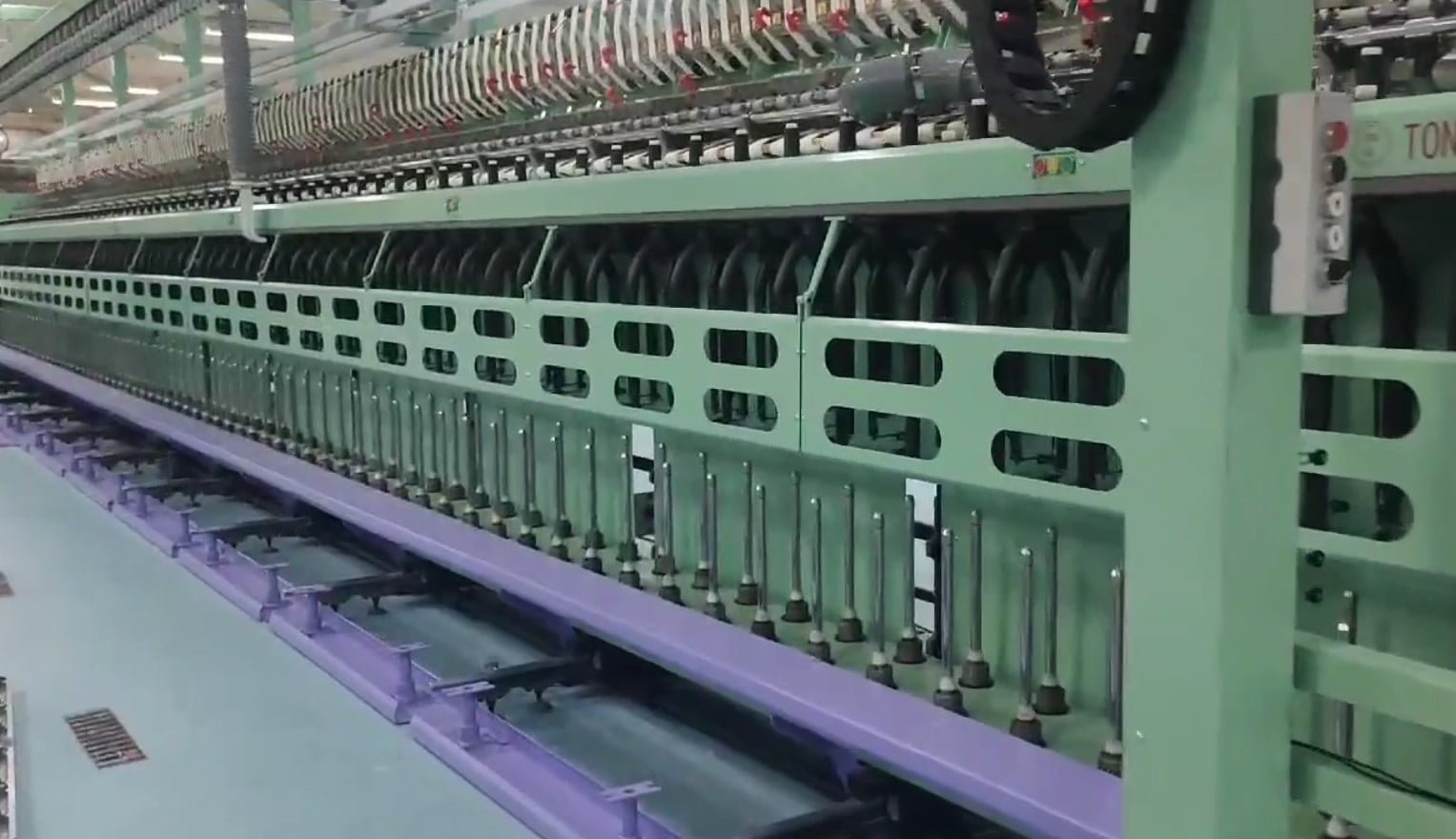

The roller weightings generally applied to the top rollers by a weight hanging below the roller beam are about 20 lbs for a double boss front roller, 14 lbs for a middle roller, and 10 lbs for a back roller, the middle and back rollers may be saddle weighted (spring weighted). In this case, the applied weight is about 20 lbs. Heavier weightings are helpful to deal with the occasional thick ends and piecing in the creel material to make even material.

Top roller weighting are very important in all the cases where the roller drafting are employed due to:

Over weighting contributes in the:

- Production of roller – Jam between the drafting rollers.

- Excessive ends down.

- Production of weaker fibres.

On the other hand under weighting produces:

- Irregular material (sliver, roving and yarn).

- Insufficient parallelization of the fibres.

- Insufficient straightening of the fibres.

- Slubs in the material.

- Waves in the sliver.

The advantages of spring weighting and top arm over dead weighting are as follows:

- The roller beam is feed from the multiplicity of weight wires and hook and is therefore easier to keep the machine clear.

- The top rollers are positioned more exactly over the corresponding bottom rollers.

- The top rollers are held by top arms and can be swung out of the way easily.

- The pressure applied is independent of the roller setting.

- The weighting is commonly even greater with synthetic rubber covering top roller than that in the old method of weighting in order to avoid from stoppages by bad drafting.