Different Parts of a Loom

Last updated on August 11th, 2023 at 08:33 pm

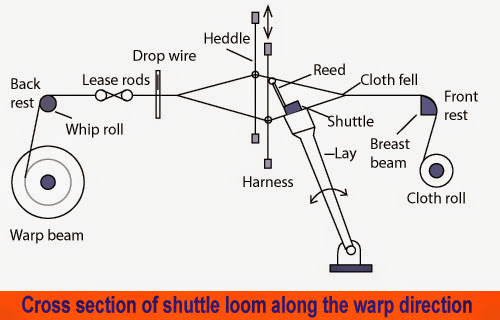

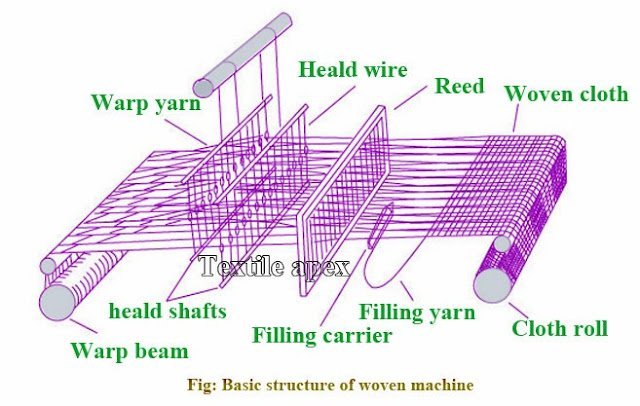

Weaving is done on a machine called a loom. All the weaves that are known today have been made for thousands of years. The precise shape of the loom and its mechanics may vary, but the basic function is the same. Warp yarns are held taut within the loom, and weft yarns are inserted and pushed into place to make the fabric.

Major Parts of a Loom

Warp Beam

The warp beam, which holds the lengthwise yarns, is located at the back of the machine and is controlled so that it releases yarns to the weaving area of the loom as needed.

Whip Roll

This is guide roller which directs the warp threads on their way to the lease rods and heddles.

Lease Rods

Another guiding device it is for the warp yarns. These are two sorts of wooden or glass rods set between the whip rolls and the heddles. Alternating warp threads can be kept separate by passing over and under these rods.

Heddles/Healds

A heddle is a wire with a hole or eye in its center through which a warp yarn is threaded. There are as many heddles as there are warp yarns in the cloth, and the heddles are held in two or more harness.

Harness

A harness is a frame to hold the heddles. The harness position, the number of harness, and the warp yarns that are controlled by each harness determine the weave pattern or interlacing.

Bobbin and Shuttle

The filling thread is wound on a bobbin which sets into a shuttle or bobbin container. As the shuttle passes back and forth through the warp shed, it releases thread from the bobbin and so forms the filling cloth.

Reed

This is inevitably a combination made up of steel wire rods set vertically in a frame. The spaces between the wires are known as splits or dents and are kept even and parallel. This is the first function of reed. Its second function is to feed the filling thread into position. To do this it has to move in a back and forth motion.

Breast Beam

The bar his is, at the front of the loom over which the cloth passes on its way to the cloth roller.

Temples

They divide at the edges of the cloth which supports to maintain fixed dimension in width.

Cloth Roller

It is located at the front of the loom, hold the completed fabric.

I simply wanted to write down a quick word to say thanks to you for those wonderful tips and hints you are showing on this site.

Have you ever heard of a decent design?? This one sucks man. The articles are great tho’.