Continuous Dyeing Method [Thermosol]

Last updated on July 31st, 2023 at 12:16 am

Working Procedure of Continuous Dyeing Process

Continuous dyeing is the most popular method of dyeing woven fabrics. The characteristics of this dyeing method are the numerous rollers which grey fabrics go in and come out dyed.

When there is a large volume of goods, it is usually better to process them continuously without the inconvenience of separating the job into batches and repeating the process several times. In this situation processing is arranged as a continuous uninterrupted sequence of events from the start to finish. The goods move at a constant rate throughout and on completion of the dyeing they are taken up mechanically at the far end of the equipment. The process is run until the whole length of textile has passed through.

Although most continuous coloration is carried out on fabric, equipment is also available for dyeing fibre in the form of loose stock, tops and tow. At the start of each process fibre is sprayed with dye, fed on to an endless rubber belt and carried to the rollers of a padding mangle, where uniform impregnation is obtained as the surplus liquid is squeezed out. In the example shown in the following figure, the loose fibre is carried through a tubular steamer, washed to remove surplus dye bath ingredients and after the application of any special finishes, dried. This general scheme of impregnation followed by fixation, washing and drying is the same for each of the continuous process.

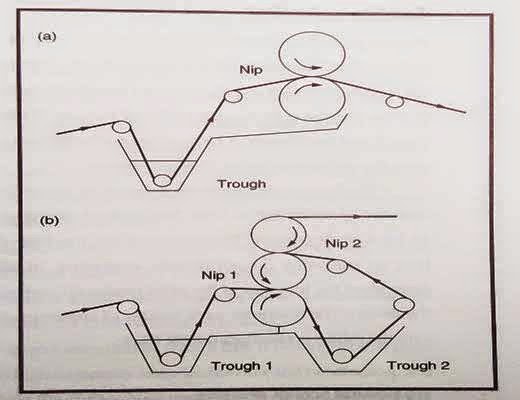

Various sequential operations are used for the continuous dyeing of fabric. An initial padding stage is common to all sequences. It involves immersion of the fabric in the dye liquor contained in a trough of minimal volume, which is kept constantly replenished from a stock tank. A liquor ratio is as low as 1:1 may be used; in general, low-substantivity dyes are used in continuous dyeing process. Next, the fabric passes in open width through a ‘nip’. The nips are the padding mangle, in which heavy rollers (called bowls), pressed closely together along their length, and are rotated in opposite directions to carry the fabric through the system at a constant speed, squeezing out the superfluous dye liquor. Heavier fabrics are passed through two consecutive troughs and a second nip, using a three-bowl mangle.

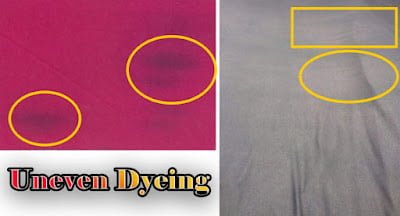

The fabric, now uniformly impregnated with dye and the appropriate dye bath auxiliaries, usually passes directly to a steamer or dry heater for fixation. In some cases, however, where evaporation of the water in the fixation chamber causes unwanted directional migration of dye, the fixation step follows a preliminary drying operation. After fixing, the fabric passes from the fixing chamber to the washing range and is dried either on heated cylinders or by some other means such as radio frequency heating. Finally it is wound onto a beam ready for transportation. The sequence is similar for all processes, but of course the dyes, additives and operating temperatures vary from one situation to another.