Causes of Faults Found in Ring Frame Yarn

Last updated on September 25th, 2023 at 11:53 pm

The Faults Found in Ring Frame Yarn and their Causes

Soft Yarn

Generally caused by slack spindle bundles, twist change wheel too large, empty bobbins not properly pushed down during doffing.

Uneven Yarn

Either travelers are too heavy or for spinning fine counts from inferior cotton.

Fuzzy Yarn

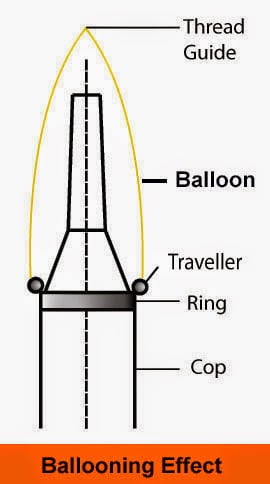

Rings too large, by ballooning or bad lubrication of ring frame rollers.

Twisty and brittle Yarn

Worn rings and traveler are too heavy or lack of humidity in spinning room.

Rough Yarn

Traveler too light, too much twist, and spindle speed too low, bobbins that are rough at the top.

Badly wound Yarn

Caused by the defective traveler motion and also by bobbin being loose on the spindle.

Tender Yarns

Imperfect traveler, waste on travelers, adjustment of ring rail not correct, thread guide not in the right position.

Hard and inelastic Yarn

Too much twisting and drafting in the draw frame and also for insufficient doubling later.

Slub

This occur when the twist in the yarn is not uniform. It appears as thick place, which has received insufficient twist. This is caused by what is called thick roving. Two rovings over lapping each other, which thus passing through the rollers without receiving the amount of twist required.

Nepped Yarns

So called because it contains small piece of hard cotton called neps. These are two kinds:

Commonly distinguish as natural neps and will neps. The former consists of short and undeveloped fibres that have become embedded in the yarn. The latter are impurities and also short fibres usually found adhering to the surface of the threads.

You may also like: The Causes of End Down in Ring Spinning

Useful informations thanks

Thanks

Hi halo sar