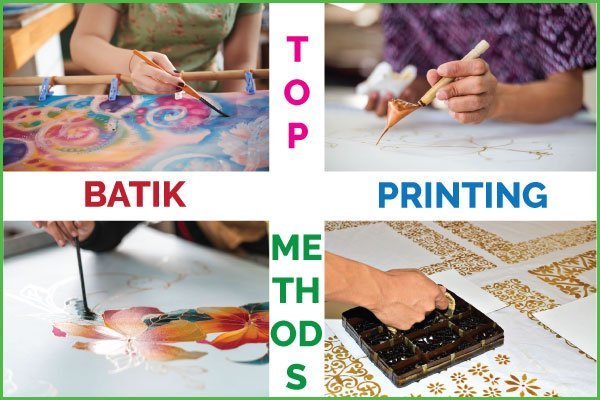

Top 5 Batik Printing Methods

Last updated on August 2nd, 2023 at 12:54 am

Batik is a traditional textile art form that originated in Indonesia. Unusual color effect can be produced employing various batik styles. It involves using wax and dyes to create intricate patterns on fabric. There are several methods of batik printing, each with its unique characteristics. Here are some common batik printing methods:

Tie-Dye Batik (Ikatan Batik)

Ties are often dyed by batik techniques. Parts of each cloth are knotted or tied with a string and then dyed, usually by dipping. In the knotted or tied places the dye solution cannot penetrate; this produces unique effects.

Hand-Drawn Batik

Hand-Drawn Batik is another batik method done by the wax resist technique. It is the most traditional and labor-intensive method. Artisans use a “canting” (a small spouted container for hot wax) to draw intricate designs on the fabric. The canting allows for precise control over the wax application. The treated areas resist subsequent printing or dyeing. After dyeing, the wax is removed. This process may be repeated with different colors to achieve multi-colored designs.

Painted Batik

Painted batik is a popular form of batik done by the application of hot wax with a thin brush on the outlines of a design. Within the outlines, a dyestuff solution is applied. It spreads evenly over the surface; after drying the fabric is steamed and finished in the usual manner. Before steaming the painted fabric is wrapped in absorbent paper. During the steaming, the softened wax is absorbed by this paper.

Screen Printing Batik

An improvement over this purely manual method is the use of a screen to print the outlines. Glue and British gum are used as mechanical resists, preventing the spread of dye solutions. These resists lines can also be colored. This method is more efficient for large-scale production of batik fabrics.

Hand Printing Batik

A multi step hand printing technique that includes the application of a substance to protect of limit desired areas of the base fabric from coloring by resisting dyestuff. When fabric is submerged in the dye bath, the chemical or wax-protected areas resist the dyestuff; dyestuff adheres to or penetrates untreated areas. The waxing dyeing and wax removal processes are repeated until design or desired effect is completed. White areas may be left white, dyed or over printed.