A Guide to Different Drying Methods in Sizing

Last updated on August 9th, 2023 at 12:01 pm

Definition of Drying

After leaving the size box, the wrap sheet gets impregnated with wet size paste to the extent of about 90% – 140% of its own weight. The process of drying involves complete removal of the moisture from the size paste and at the same time retaining the water in the yarn. This is particularly so in the case of cellulose or any other natural fibre yarns. It is to be noted here that the degree of drying largely influences the yarn properties such as strength, flexibility, brittleness, and plasticity and so on. Also, the rate of drying determines the speed and production of the sizing machine. Hence it is to be effected in such a way so as to retain the desirable properties of the yarn and economy maintained concerning production and energy consumption. The time and temperature of drying play an essential role. Proper care and caution are to be exercised in this aspect; otherwise, it would result in over or under drying of yarns that could create problems in the subsequent process. There are different methods of drying-sized yarns.

Methods of Drying

There are three important methods of drying in sizing. These are:

- Conduction method

- Convection method

- Radiation method

- Multi-cylinder Drying

Conduction Method

In this method, the warp sheet’s drying is affected by conducting or transmitting heat from the drying cylinder’s metallic surface, which is steam heated. This is also known as the contact type of drying and is most popularly used in most slasher sizing machines. It is also very economical concerning energy consumption. The only drawback with this method is at a certain degree of flattening takes place due to contact of yarn with cylinders.

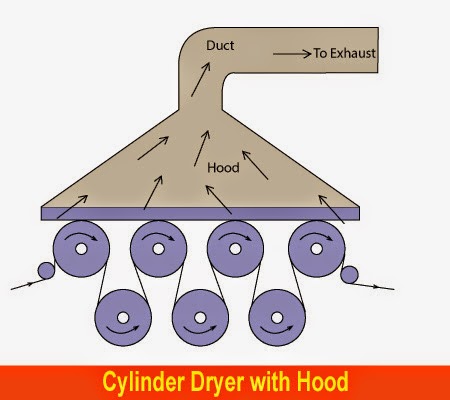

Convection Method

In this method, the drying of the warp sheet has affected the circulation of hot air around the drying zone. The air may be heated either electrically or by steam. Fans and ducts circulate the hot air. The main advantage of this method is that the yarn is not flattened as in the previous case.

Radiation Method

In this method, the wrap sheet’s drying is affected by heat transferred to it by direct radiation. Electrical heaters are used for this purpose. Energy is transmitted to the yarn in heatwaves through electromagnetic radiation, which removes the water present in the yarn. In this method, as in the previous one, no flattening of yarn takes place since the yarn has no contact surface. It is considered very poor concerning the economy in energy consumption and hence is seldom used. It is, however, suitable for laboratory trials as well as large-scale operations that need quick drying.

Multi-cylinder Drying

This method is most commonly adopted in industries. In this case, the number of drying cylinders used ranges from 5 – 13. The size of the cylinders is much smaller compared to those used in the convectional twin-cylinder machine. In some exceptional cases, where dyeing and sizing are done simultaneously, such as in the dye-sizing operation for denim, the number of drying cylinders is much more and may go up to 32. The cylinder diameter is about 762 mm. Steam pressures usually are higher and vary with different places. In some areas, the steam pressures range between 2 – 2.5 kg/cm2, whereas in other sites, it can range as high as 5 – 7 kg/cm2; higher steam pressures permit more incredible running speeds. The cylinders of a multi-cylinder slasher machine are arranged in two rows.

One of the advantages of the multi-cylinder is that the cylinders are positively driven, and this prevents any undue tension on the yarn. The cylinders rotate smoothly since they are mounted on ball bearings. Each cylinder is provided with an independent steam supply valve. Each drying cylinder’s temperature can be individually controlled to suit the type of yarn and the machine. Several parameters, such as type of yarn, speed of the device, number of cylinders, etc., govern each cylinder’s temperature. The first cylinder is at a higher temperature, and the temperature falls at successive cylinders. The last cylinder is kept cool, so the dried yarn leaves the drying zone in a cool condition. The first one or two cylinders are coated with Teflon to prevent the problem of ‘smudging’ (size stain). The cylinder temperatures vary with the type of yarn sized. It ranges from a maximum of about 1500C for cotton yarns and a minimum of 800C for acetate rayon filament. Polyester and polyamide yarns are dried at 85 – 900C.

You may also like: A Guide to Slasher Sizing Machine

Very nice article.

Helpful article ✔

Hello! Someone in my Facebook group shared this website with us, so I came to give it a look. I’m enjoying the information. I’m bookmarking and will be tweeting this to my followers! Wonderful blog and amazing design and style.