Wool Production Process | Difference between Worsted and Woollen Systems

Last updated on January 7th, 2026 at 10:20 pm

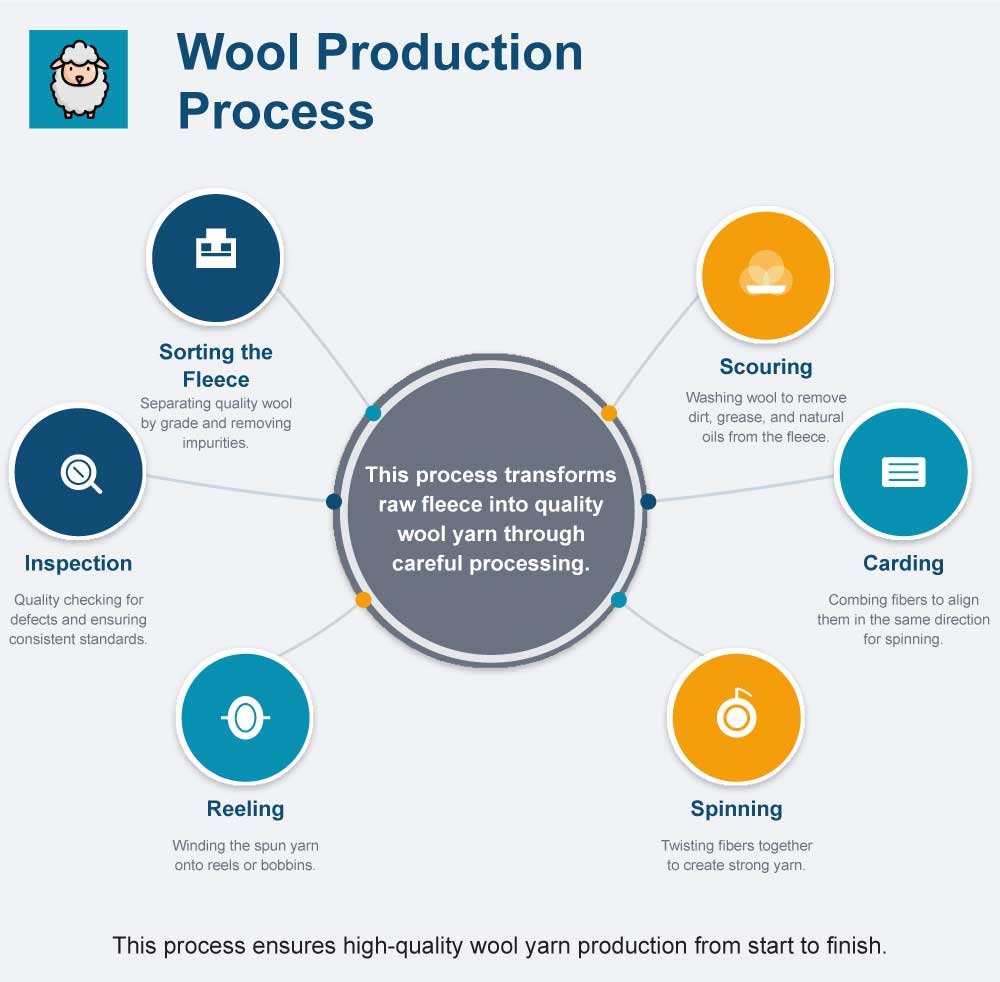

Wool Production Process

Sheep are sheared to remove the fleece in the spring season. Wool removed from animals that have been slaughtered is referred to as ‘pulled wool’. Pooled fibre is inferior in quality to fleece or tip wool, as it is less lustrous and elastic. It can be spun into yarns by the woollen or the worsted system.

Sorting the fleece

Each wool fleece yields many diverse grades of these fibres. A skilled sorter can separate them by qualities called sorts.

The shoulder wool generally has the best fibre. Fine fibres that are comparatively long are reserved for sheer wool fabrics and worsteds. Medium fibres of the shortest length are suitable for woollens, while coarse fibres are suitable for carpets.

Scouring

It removes oils, grease, sweat and some of the dirt and impurities from the fleece. The fleece is washed several times in a warm, soapy alkaline solution. Scouring converts a fleece of 8 lbs to one of 3-4 lbs. The weight loss results from the removal of lanolin. This lanolin is recovered for use in cosmetics, etc.

Carding

All the fibres are carded. Fine wire teeth mounted on a cylinder separate the fibres and make them somewhat, almost totally, parallel. This procedure also removes remaining vegetable matter from the fibre. Yarns that have been carded are known as woollen yarns. Woollen yarns are carded only, and the fibres are rather random in arrangement. They still contain foreign matter which is removed by carbonisation. i.e., treating with acid.

Spinning

Spinning puts in the needed twists. The slivers are wound from one spool to another, and while doing so, the yarn is provided a twist. These yarns are much thicker as compared to cotton and silk. The yarns are sold to weavers on these spools or in skeins.

Twisting

Twisting is spinning two, three or four yarns together. Two-ply yarns are used for weaving and machine knitting. Three and four plies are utilised for hand-knitting.

Reeling

Worsted yarns are wound around and reeled into skeins.

Inspection

Inspecting the skeins and putting them into bundles of 40 lbs each completes worsted yarn manufacture.

Combing

Before combing, the decision is made whether the fibres are to be utilised for woollen or worsted yarns and fabrics. Combing aligns longer fibres in a parallel manner so that the resulting “worsted yarns” are smoother and stronger. The fibres are combed by passing through the combing machine. Here the fibres are laid in a very orientated arrangement.

Short fibres are removed, and the remaining fibres are pulled into a twisted strand known as ‘top’. The short fibres are known as ‘noils’. Wool tops can be dyed in this form, or worsted yarns can be constructed and then dyed.

Difference Between Worsted and Woollen Systems

- Worsted are chosen for special uses where it is desirable to get a hard surface finish, greater durability, and sharper colouring.

- Under the worsted system, the treatment of wool from the raw state to the finished state makes it possible for the fibre to be twisted in such a manner as to create a smoother or harder surface. This is the essential difference. Fibres can be twisted before weaving.

- Worsted fabrics generally have a smoother texture than woollens.

- Worsted takes shine more easily due to the twist.

- Worsted cloth is less bulky and lighter than woollens.

- Worsted is made up of a better grade of yarn.

- Worsted is easy to tailor and drape.

- Worsted does not easily sag and hangs a crease well.

- Worsted cloth has greater tensile strength than woollens.

- Worsteds last longer than woollens.