A Guide to Different Drying Methods in Sizing

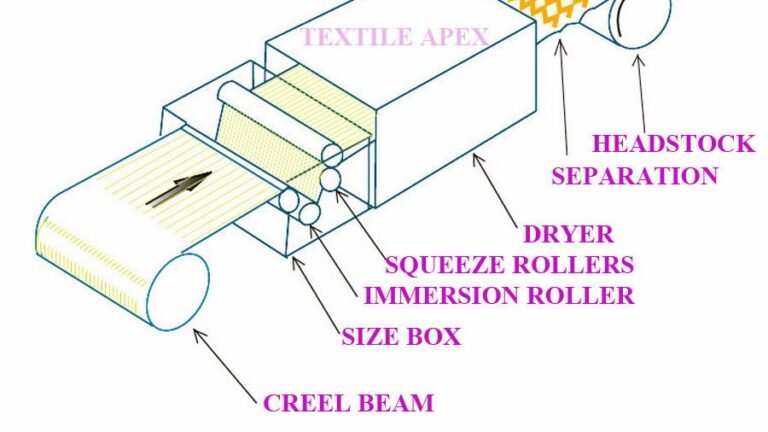

Definition of Drying After leaving the size box, the wrap sheet gets impregnated with wet size paste to the extent of about 90% – 140% of its own weight. The process of drying involves complete removal of the moisture from the size paste and at the same time retaining the water in the yarn. This[…]