What is Combing? Working Principle of Cotton Combing

Last updated on August 8th, 2023 at 12:24 am

Definition of Combing

Removing short fibres, neps and impurities by using combs is called combing.It is the process of separation of long desirable fibres of same length from the short fibres, neps and all remaining foreign materials of the fibre stuck. The fibres also become straight and parallel.

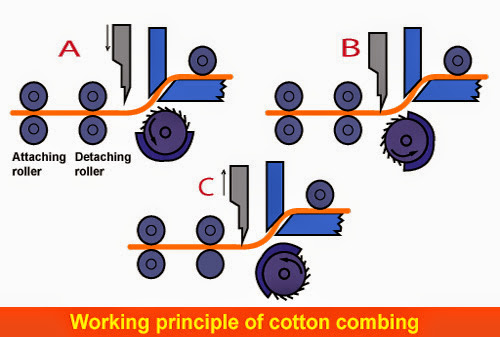

Working Principle of Cotton Combing

All the combers operate intermittently, both ends of the fibres are combed separately by needles and the continuity of the strand is maintained by an ingenious method of piecing up the separated combed tufts, shortly, the process is operated as follows –

- The lap prepared for combing is fed into the machine between the feed roller and the bottom nipper. At the front of the nipper, the top nipper is positioned to gripe the lap as it passes to be combed at the front end of a fringe.

- The protruding fibres beyond the nipping point are combed by the passage of raws of needles fastened of a cylinder and situated below the lap. The cylinder with the needles revolves and carries away the short fibres, neps, and impurities from the front part of the fringe. The wastage are removed from the cylinder needles by a brush and collected around an aspirator.

- When the cylinder comb completes its action, the top comb then comes down to perform its action at the back part of the fibre fringe. Meanwhile, the partly combed fibres are withdrawn through the top comb by detaching rollers.

- When all the combed fibres have been withdrawn by the detaching roller, the top comb is withdrawn and the cylinder comb operates on new sets of fibres as before.

- The top comb operates again but before the rollers draw away the newly combed fibres, then turn backwards a little so that, the new fibres can be over lapped with those withdrawn in the previous combing and in this way the continuity of the combed web of fibres is maintained.

- The combed web delivered by the rollers is passed through a trumpet to consolidate the fibres and to make a sliver which is pulled along a table alongside other slivers from the other combers delivered by the same machine. 6 or 8 slivers are drawn into a single sliver by a drafting mechanism at the end of the sliver table and passes into a sliver can.

You may also like: Combing: Definition, Objects and Necessity

Very helpful topics.

Nice article.

Thanks.

Thanks.